Walterscheid PTO Shaft: An Overview

The Walterscheid PTO shaft is a critical component for various machinery and agricultural equipment. This specific model boasts a size of 2100, Lz of 860mm, and a profile of 1 3/8″ 6 splines. Other features include its universal joint size A profile and B profile (both 22 x 54,8mm), an automatic push-pull lock, operating instructions included for ease of use, and a weight of 4.00kg.

Key Features of a PTO Shaft

Power Take-Off (PTO) shafts play a pivotal role in the functioning of machinery. Here are five key characteristics that set them apart:

- Power Transfer: PTO shafts are designed to transfer the power from the engine to another piece of the equipment.

- Versatility: They are used in various types of machinery, including agricultural and industrial equipment.

- Customizable: PTO shafts can be customized to meet specific power and torque requirements.

- Durable: They are designed for heavy-duty use and can withstand harsh working conditions.

- Efficient: PTO shafts help enhance the overall efficiency of the machinery.

Our PTO Shaft: A Perfect Weasler Replacement

We produce PTO shafts that are fully compatible with Weasler sizes and installation methods. Our PTO shafts can perfectly replace Weasler components, providing a seamless transition and maintaining the efficiency of your machinery.

Selecting the Right PTO Shaft

Choosing the right PTO shaft involves considering several parameters:

- Length: This is the distance between the transmission device and the receiving device.

- Rated Power: The power that the PTO shaft can handle.

- Shaft Type and Connection Method: The type of shaft and how it connects to the machinery.

- Torque Transmission Capacity: The amount of torque the PTO shaft can transmit.

- Environmental Requirements: These include the need for a protective cover, sealing performance, and durability.

- Safety Features: Reliable anti-cardan devices, anti-card pins, etc.

- Compatibility: The PTO shaft should be compatible with the machinery it is intended for.

- Certifications: It’s important that the PTO shaft has relevant certifications, like CE.

Importance of CE Certification

Having a CE certification is crucial for PTO shafts for several reasons:

- Compliance with EU Regulations: A CE certified PTO shaft complies with EU regulations and standards, ensuring its design, manufacture, and use meet the European market requirements.

- Market Entry: CE certification is a prerequisite for selling PTO shafts in the European market.

- Reliable Safety Performance: A CE certification provides a reliable guarantee of the PTO shaft’s safety performance.

- Confidence: A CE certified PTO shaft instills confidence in the product’s quality and safety.

Our Certified PTO Shafts

Our PTO shafts come with CE, TS/16949, and ISO 9001 certifications, ensuring their quality, safety, and reliability.

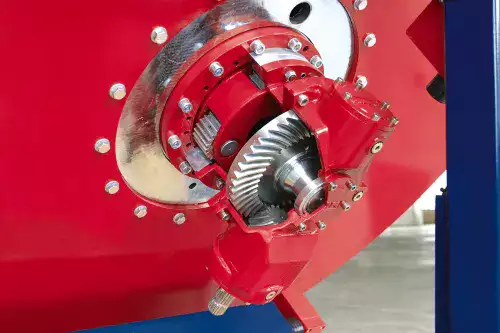

PTO Shaft Structure

A PTO shaft consists of several components, including the housing, drive shaft, universal joint, protective cover, and connectors. Each part is made of high-quality materials to ensure durability and efficiency. We also sell individual parts.

Application of PTO Shafts

PTO shafts are used in various applications:

- Agricultural Machinery: They are commonly used to connect tractors and agricultural equipment such as mowers, harvesters, straw crushers, sprayers, mixers, etc.

- Industrial Equipment: PTO shafts drive rotating equipment like pumps, generators, centrifuges, mixers, etc.

- Transportation Equipment: They are also used to drive certain transportation equipment like trailers, semi-trailers, and towing vehicles.

- Solar Systems: PTO shafts are used to rotate and adjust tracker photovoltaic panels.

Adjusting the Length of a PTO Shaft

Adjusting the length of a PTO shaft involves the following steps:

- Remove the plastic protective cover.

- Shorten the inner and outer tubes to the required length.

- Remove burrs with a file.

- Shorten the inner and outer plastic tubes to the required length.

- Oil the inner steel tube and reinstall the PTO shaft plastic protective cover.

About HZPT Group

HZPT Group is a leading player in the PTO Shaft market in China. We specialize in the development, production, and marketing of power output shafts, industrial universal joints, and automotive drive shafts. Our products enjoy a stellar reputation among customers in Europe, the United States, Asia, Australia, and North America. We provide customization and OEM services, and our products have earned CE, TS/16949, and ISO 9001 certifications. Apart from PTO shafts, we also supply related products such as agricultural gearboxes, chains, sprockets, pulleys, couplings, and agricultural machinery parts. agricultural gearbox“>

agricultural gearbox“>

Author: Miya