Solution Description

Embroidery 3d watertight non woven chinoiserie home art wallcovering

Item Particulars

| Product name | Embroidery 3d waterproof non woven chinoiserie house artwork wallcovering |

| Kind | Wall fabric design |

| Model number | Flower Language 2 |

| Excess weight | Jacquard to formaldehyde wall cloth |

| Measurement | two.8*60M |

| Port | ZheJiang or HangZhou |

| Provide ability | one hundred thousand square meters/thirty day period |

| Delivery time | 15-twenty five times |

| Technological innovation | Jacquard |

Functions:

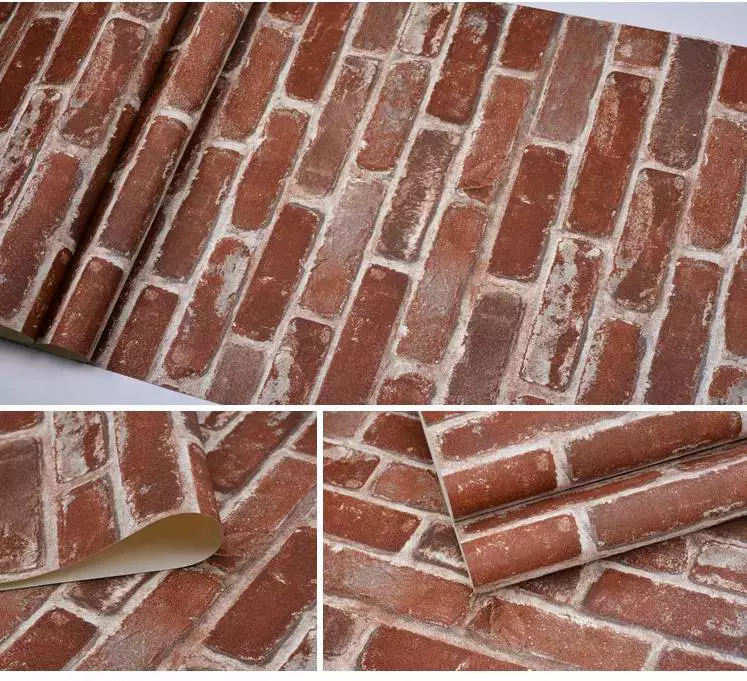

- Peel and stick mosaic tile,manufactured of PVC, eco-helpful resources.

- Water-resistant, new non-toxic antifouling, adaptable, heat & humidity resistant

- Suitable for kitchen area, lavatory backsplashes, bedroom walls, laundry rooms and so on.

- With vivid color effect and really feel of transparent glass tile.

- Straightforward to cut it with scissors or utility knife, Basic, No certain tools necessary!.

- Straightforward to thoroughly clean the stains with soaked gentle fabric or cleanant.

Our Manufacturing facility

HangZhou Shenlai Investing Co., Ltd. is a subsidiary of HangZhou Shenlian Baosu Industrial Co., Ltd. and HangZhou Junlilai Industrial Co., Ltd.

The company specializes in the revenue of wallpaper and wall masking at property and overseas.

The company has its very own style crew and creation cooperation producers.

The organization has overseas markets which spread in Southeast Asia, Asia, South America, Russia, Europe and other locations.

The organization have its own abroad warehouses in Vietnam, Malaysia, Thailand and other countries to guarantee well timed delivery

The company have established an abroad staff with initial-class service and first-course advertising and marketing.

FAQ

1. Q: Are you manufacturing facility or trading organization?

A: We are professional wallpaper manufacturing facility.

2. Q: How long is your shipping time?

A: T15~thirty times soon after order comfirmed and deposit gained.

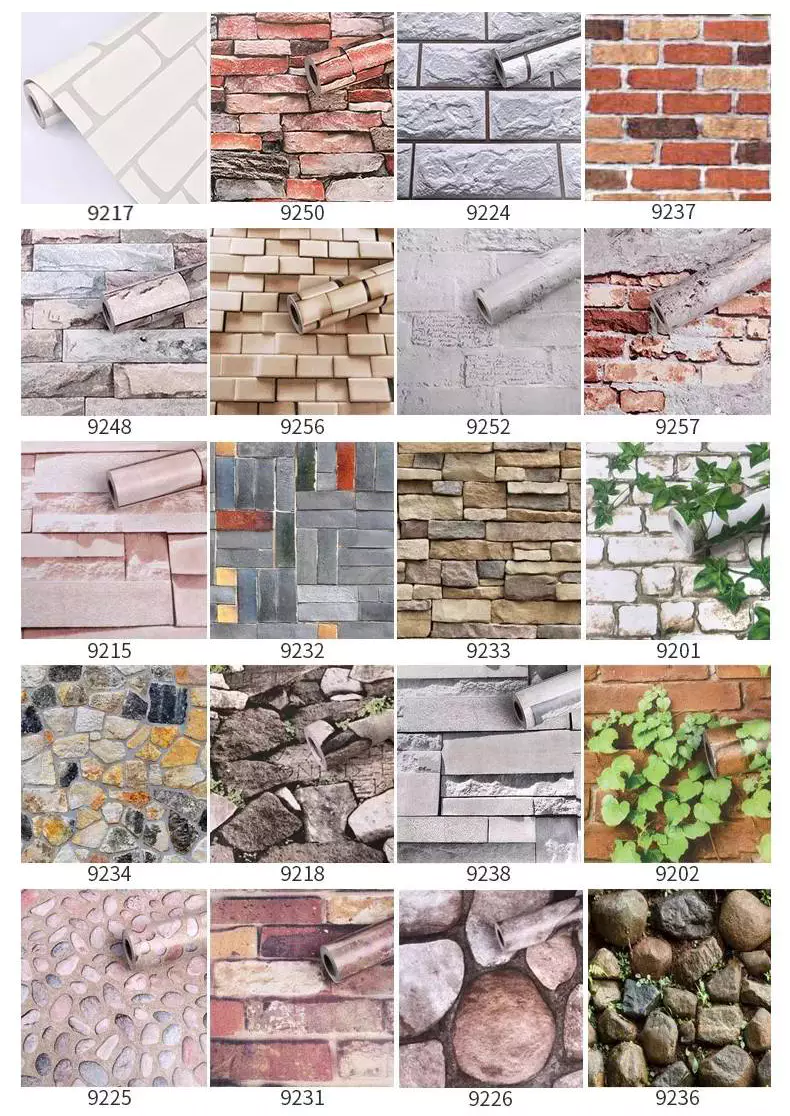

three. Q: How many wallpaper collections do you have?

A: We have more than 50 collections for alternative.

four. Q: Do you provide free of charge samples?

A: Indeed, we offer free of charge samples for totally free demand.50 percent meter sample.

five. Q: Which dimensions do you have?

A: Wall paper: 0.53*9.5m , 0.fifty three*10m, 1.06*10m, 1.06*15.6m

Wall Cloth: 2.8*60m

6. Q: What variety of wallpaper do you produce?

1. PVC(Vinyl) wallpaper,

2. Non-woven wallpaper,

3.Basic non-woven wall fabric

4. Jacquard to formaldehyde wall cloth

|

US $3.00 / Meter | |

50 Meters (Min. Order) |

###

| Style: | Modern |

|---|---|

| Surface Technology: | Printing |

| Color: | Color |

| Standard: | 2.8m |

| Feature: | Decoration, Waterproof, Moisture-Proof |

| Type: | Paper Wallpaper |

###

| Samples: |

US$ 3/Meter

1 Meter(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Item name | Embroidery 3d waterproof non woven chinoiserie home art wallcovering |

| Sort | Wall cloth design |

| Model number | Flower Language 2 |

| Weight | Jacquard to formaldehyde wall cloth |

| Size | 2.8*60M |

| Port | Shanghai or ningbo |

| Supply ability | 100000 square meters/month |

| Delivery time | 15-25 days |

| Technology | Jacquard |

Different Types of PVC Wallpaper

Whether you want to decorate your home or business, you can find the perfect PVC wallpaper to suit your needs. You can choose from a range of styles, including grasscloth, metallic, peel and stick, and paper backed wallpaper. You can also find non-pasted wallpaper to give you a little more flexibility.

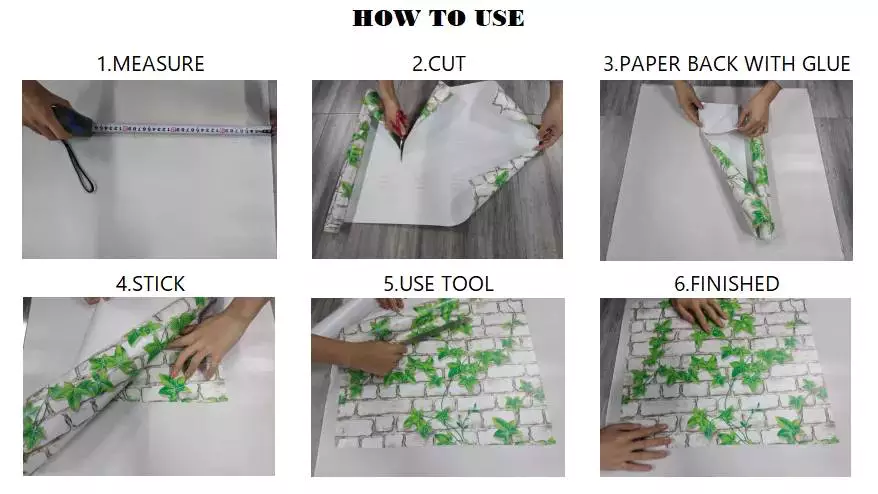

Peel and stick

Using peel and stick pvc wallpaper is an effective way to transform an awkward wall into something beautiful. The best peel and stick wallpaper is also easy to install and remove. However, before you apply it to your wall, there are a few steps you need to follow.

First, you need to measure your wall. The standard size for this type of wallpaper is about 12 feet long and 2 feet wide. To do this, you’ll need a level and a straightedge. Use the straightedge to draw a line from the ceiling to the baseboard. It’s important to do this so you can lay out your wallpaper in a straight line.

The best way to get a straight line is to start at the center of your wall and work outward. You can use a smoothing tool to help you achieve this. If you don’t have one, a microfiber cloth will do the trick.

You’ll also need to use a level to draw a line from the ceiling to your baseboard. This will help you line up the seams of your wallpaper when you’re finished.

It’s also important to choose the right paint. Most manufacturers recommend using eggshell or semi-gloss paint. Some people choose to apply their wallpaper in sections, rather than all at once. This allows you to reuse the wallpaper in different parts of your home.

While choosing the right wallpaper, you should also consider the type of adhesive the wallpaper is made of. The adhesive can affect the way your paint finishes. Some wallpapers come with specialty surfaces, like chalkboard and whiteboard wallpaper. You can also buy decals from CZPT.

Paper backed

Depending on the type of vinyl used, paper backed vinyl wallpaper is either washable or scrubbable. It is also moisture resistant. It is easy to install and maintain. It can be applied to most rooms in a home. It is also inexpensive, making it a popular choice.

Paper backed vinyl wallpaper is made of a paper backing that is laminated to a vinyl sheet. It is often called solid sheet vinyl wallpaper. This wallpaper is a durable material that can withstand moisture and mildew. It is also scratch resistant. It is ideal for children’s rooms.

Natural fiber wallcoverings are made from dyed or unpasted natural materials. They offer a natural texture and shading. They are also great for low-traffic areas.

Woven fabric backings are made from woven cotton or drill cloth. They are very durable and can be used in commercial applications. They are tested to be able to withstand minimum requirements.

Natural fiber wallcoverings also require special cleaning techniques. They are also susceptible to moisture. They also contain natural materials such as grass, coir, hemp, and jute. They can also be difficult to hang.

Non-woven fabric backings are made from ground wood or ground cotton, cellulose, or wood pulp. They are also woven with textile fibers or pigments. They are also stain resistant. They can also be vinyl coated.

Unlike natural fiber wallcoverings, solid sheet vinyl wallpaper is not washable. It is also not suitable for hard scrubbing. It is not recommended for high traffic areas.

PVC wallpaper is made from polyvinyl chloride. It is also waterproof and has a strong design. It is affordable and easy to maintain.

Paper backed vinyl wallpaper is a great choice for kitchens. It is also a good choice for bathrooms.

Non-pasted

Choosing the right type of non-pasted wallpaper can be an important decision. Some types of wallpaper are easier to install than others, and some require more effort than others. Whether you are new to installing wallpaper or you just want to avoid the hassle, you should know the differences.

One of the most important steps in hanging wallpaper is prepping the wall. This includes removing the wallpaper, applying the adhesive, and smoothing the paper. Using a razor or putty knife to guide the cuts is helpful. You should also test the adhesive strength of the wallpaper to make sure it’s safe. If the adhesive is too weak, the seams may open when the wallpaper dries.

The best type of wallpaper to use in damp areas is vinyl coated. This type of wallpaper is durable, stain resistant, and grease resistant. It also has a thick, raised design that can cover wall damage. It is also a good choice if you want to cover a wall in a unique color.

There are many types of non-pasted wallpaper available, including paper-backed and solid sheet vinyl. Each has its own pros and cons. If you are looking for the best non-pasted wallpaper, you should shop at CZPT. Whether you are looking for a traditional design, or a custom design, CZPT can help you find the right wallpaper for your home. You can shop by brand, style, or unique feature.

For the best non-pasted wallpaper, check out CZPT’s carefully curated selection. You can choose a design, style, or unique feature that you like, and the site will send you the wallpaper quickly. You can also upload your own designs to create a custom wallpaper for your home.

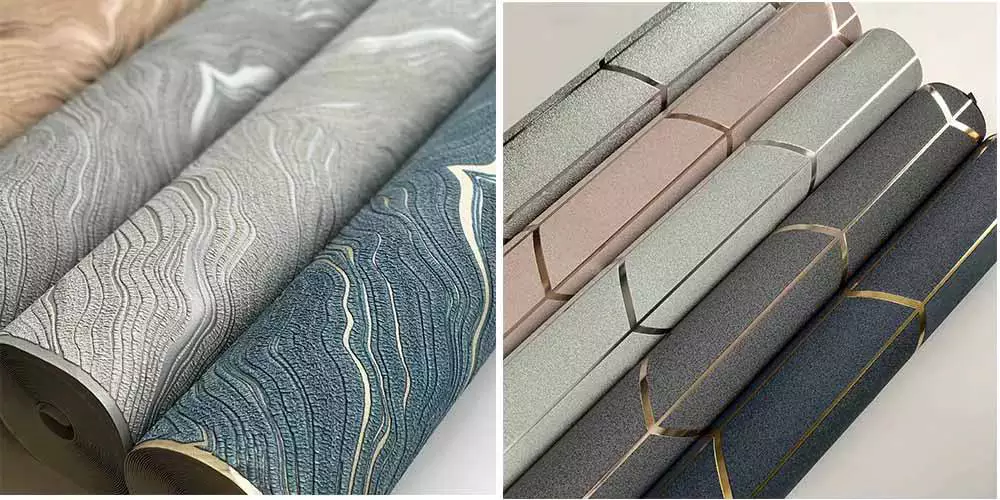

Metallic

Whether it’s a small apartment or a sprawling mansion, there’s a metallic PVC wallpaper to suit your style. The material is resistant to water, stains, and fire, making it an ideal surface for any interior. It’s also easy to clean. The material is also non-toxic, so it’s suitable for babies and the elderly.

The best part is, it’s cheap. You can get a roll for as little as a few bucks. That’s a big deal, since a few rolls of wallpaper can go a long way. Besides, you don’t have to worry about the flimsy stuff tearing off, a la drywall. A metallic patterned wallpaper is a great way to add some sparkle to any space, whether it’s a modern bedroom or an old man’s den. The material is also durable enough to withstand years of wear and tear. Moreover, it’s an easy way to change up your home decor. And with the right paint and a little paint, you can have an entire room covered in metallic style in no time at all. It’s also the most cost-effective way to add some pizzazz to your home.

A metallic patterned wallpaper is also a great way to add some modern flair to your bedroom, living room, or office. The material is surprisingly durable and easy to clean. Besides, it’s also non-toxic, making it an ideal surface for any interior. You can even find a metallic patterned wallpaper that’s non-stick, making it a great choice for baby’s room. So, what are you waiting for? Order your metallic PVC wallpaper today! You’ll be happy you did. And you’ll have a shiny new interior to show off for years to come.

Grasscloth

Grasscloth wallpaper is made from a variety of natural fibers. It is hand-woven and adhered to a light backing of rice paper. It is ideal for a living room or bedroom.

Grasscloth wallpaper comes in rolls that are sold in linear meters. You can choose from a variety of designs and colours. The most common style is the horizontal grasscloth pattern. This style provides a vertical and horizontal pattern that adds texture to the room.

Grasscloth is not the easiest wallcovering to install. It requires specialized know-how and a specific set of tools. It is best installed by a professional installer.

Installation of grasscloth wallpaper requires a high level of skill and expertise. The material is very delicate and requires careful handling. This type of wallpaper also requires a special adhesive.

Installation requires a special mix of adhesive based on the weave density. It is also recommended that the wall be primed with a 100 percent acrylic pigmented primer. This will help block any bleed-through.

Grasscloth wallpaper is best installed in an area that does not get wet. It expands when wet. It is not recommended for use in bathrooms or sunrooms. It can also be damaged by moisture from cleaning products. It also requires a good amount of upkeep.

When buying grasscloth wallpaper, it is important to choose a pattern that does not repeat. This will help to prevent the wallpaper from looking uneven. A striated pattern will make the wallpaper look off-set on the wall.

Most grasscloth wallpaper is made from reeds, hemp, bamboo, arrowroot grass, and seagrass. These fibers are grown on plantations that do not use pesticides. They are colored with water-based vegetable dyes.

editor by CX 2023-06-27